Knorr-Bremse Rail Systems (UK) has reinforced its commitment to engineering excellence and innovation with a significant investment in state-of-the-art tools at its Melksham site, including the Keyence VHX-7000 Digital Microscope and the Laser-Based Elemental Analyzer EA-300 Series.

Richard Jackson-Lockyer, head of quality at Knorr-Bremse Rail Systems, said: “In the rail industry Knorr-Bremse is not just one step ahead; we are leading the way by investing in these technologies.

“Our investment in just the beginning. By adopting leading-edge technology, we are creating a culture of excellence and inspiring the next generation of engineers. These tools will help us remain ahead of the curve, ensuring our engineers and our company continues to drive success and shape the future of quality and engineering in the rail industry.”

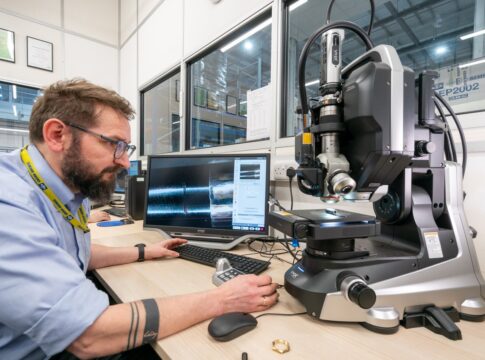

The Keyence VHX-7000 Digital Microscope enables unparalleled precision in product inspection, offering the engineers in Knorr-Bremse’s Plant Quality Team the ability to examine components at a microscopic level with incredible clarity. By creating detailed 3D images, this advanced system helps identify even the most subtle flaws or defects before they escalate into larger issues. This investment not only ensures superior product quality, but also supports waste reduction and streamlined production processes, aligning with Knorr-Bremse’s goals of efficiency and sustainability.

Equally impressive is the addition of the Laser-Based Elemental Analyzer EA-300 Series, a tool that revolutionises the way materials are analysed. By using laser technology to assess the chemical composition of materials, the EA-300 provides precise, real-time results without causing damage to the material. This capability enables faster identification of inconsistencies or potential material issues, ensuring products meet the highest standards of performance and durability. Previously, such investigations required costly outsourcing and lengthy process times. The new analyser eliminates these challenges, providing Knorr-Bremse with a faster, more efficient internal solution.

Richard added: “These advanced technologies would normally be used in the motorsport or aerospace industries. We believe it is unique in the UK rail industry. What would normally take hours to measure can now be done in minutes. It is efficient and precise. It means that we are able to rapidly respond to our customers’ needs so that if they have a problem in the field, we can establish the cause of it very quickly.”

This latest advancement comes on the heels of Knorr-Bremse’s investment in a portable handheld 3D scanner, a cutting-edge metrology-grade device that captures accurate and repeatable 3D measurements of complex surfaces both on-site and out in the field.

Ireneusz Turzynski, plant quality supervisor at Knorr Bremse, said: “Knorr-Bremse is a progressive company, which is why we are making large investments in advancing technology. It is about ensuring customer satisfaction, time efficiencies and adding value.

“The handheld 3D scanner is invaluable for measuring rail components, enabling us to improve product development, shorten time to market, and reduce development costs. Its ability to operate without external tracking devices or tripods makes it a reliable, stand-alone tool for inspection and reverse engineering of components.”

The integration of these tools underscores Knorr-Bremse’s unwavering focus on innovation and leadership in the rail industry. By embracing advanced technology, the company not only enhances its current operations, but also sets the stage for long-term growth and industry leadership.

Richard Jackson-Lockyer concluded: “At Knorr-Bremse, we believe that technological excellence isn’t just a tool – it’s at the heart of everything we do. With these recent and significant investments, we are not only improving quality and engineering; we’re taking a big leap into the future.

“Rail is a safety critical industry and it’s essential that our customers can rely on and have confidence in the information we provide. This is about ensuring customer satisfaction, improving time efficiencies, and delivering safe, reliable, and high-performing products. We have advanced from measuring things physically to being able to analyse them at a deeper level, for the benefit of our customers.”

Image credit: Knorr-Bremse Rail Systems (UK)